World leaders in theme park ride engineering, Amusement Technical, regularly retrofits Sprint Electric DC Drives into renowned fairground rides such as the Frisbee, Ferris wheel, Breakdance, Magic, Lift-hills, Crazy buses, Pirate boats and powered roller coasters.

Built in the 80’s & 90’s these giant, German-built popular rides were in high demand, and many are still going strong decades later. Amusement Technical lovingly upgrade the rides and in the process they update the drives and safety control systems so that they can continue to operate safely for many years to come.

The drives that control the motors need to be workhorses as they run hard and virtually non-stop for 8-12 hours every day. They need to be fast and responsive as they have to deal with sharp changes of direction and speed at full load. Above all they need to operate reliably in the leisure industry where safety is paramount.

Many of these behemoths require an incredible high starting torque where they might be required, on a command start, to vertically lift a heavy load from zero. They might be required to suddenly accelerate incredibly quickly and/or then stop dead. Or they might control a chassis to rotate or even control a large pendulum swinging action.

Although AC variable speed drives have been available for many years, DC still offer many advantages for this application due to the ability to produce full torque at zero speed and throughout the speed range. AC drives are also less resilient for the regenerative loads that are distinct to these applications.

These large rides create huge kinetic energies that need to be captured if the ride is to operate safely. Sprint Electric’s 4Q Digital DC Drives provide instantaneous power and control of even the heaviest load – easily able to capture kinetic energy and safely distribute back into the mains supply grid.

The PLX225 drive is perfect for retrofitting into fairground rides due to its 4Q regen capabilities. This allows the drive to catch a load, then speed up or slow down to keep spinning or swinging. An AC drive would not be able to cope with this sort of ‘shock loading’ but a DC Drive takes this all in its stride. With a range of inbuilt safety features, Sprint Electric DC Drives are a perfect fit for automating large rides.

Take the Frisbee ride for example. Weighing in at around 20 tonnes, this is a monster of monsters, even empty. This beast of engineering is able to thrill up to 48 people at a time. If you multiply that by an average adult at 80kg, the main disc potentially has to swing a total additional weight of 3,840kg (or just under 4 tonnes of load!). But that’s not all. This disc then needs to spin super-fast at load and within 1½ rotations massively accelerate up to 20 rpm! (To put that in perspective, most fast fairground rides rotate at around 11 rpm with 13 rpm as a maximum).

Director of Amusement Technical, Sean Brian, explains that he has upgraded 4 of these Frisbee rides recently and each one requires x3 DC Drives. Two for the swinging action and 1 for the rotation. Retrofitting is a significant part of Sean’s business, and he relies heavily on Sprint Electric for the DC Drives. He mainly uses the PLX drives’ built-in functionality programming, the internal function blocks that are integral to the Sprint drives, to control the required path of the ride. But for complicated programming or extra functionality he also uses the savvy software finding the graphical display easy to work with. He commended Sprint Electric on their “great after sales and technical support”, commenting:

“I have used Sprint Electric for over a decade now and have always found them to be fabulously responsive. They always have stock and their after-sales & technical support is second to none. A 2 day / 3 day turnaround is usual and their cost is reasonable, unlike other drive suppliers where the normal turnaround can be 8+ weeks and parts can cost 60% of new drive… When faced with a time critical issue on one occasion, they even repaired a drive while my driver waited! Plus, Sprint offer parts which other manufacturers don’t do.”

Sean Brian, Director, Amusement Technical

OTHER FAIRGROUND RIDES RETROFITTED WITH SPRINT ELECTRIC DC DRIVES

MAGIC

Retrofitted with 2 drives, using 1 for the main rotation and 1 for the central lifting ring that works on hydraulics. These are a feat of engineering with a turntable sporting 4 arms controlling 3 cars with 4 seats each. Sean estimates the load is 75 tonnes at the centre.

BOOSTER

This DC Drive retrofit requires 45kw for the rotation and 2 x 75+ kw (to 95 kw) swing. Sean uses Sprint Electric PLX115’s, one at the centre and one at displaced at 20° which gives an additional boost as the swing travels through.

FERRIS WHEEL

Balance is critical for these huge stature wheels and the DC drives are programmed with PLC software to load the 48 gondolas with a repeating pattern of four loading positions.

DRAGON COASTER

This is a great example of a powered roller coaster; another example is The Flying Carpet. Both do not just rely on gravity to complete the circuit. Powered roller coasters keep hold of the load all the way around the track as the load case changes, whereas the Frisbee, outlined above, lets the load go and then ‘re-catches’ it. The dynamics of the track need to be calculated carefully and the drive programmed to maintain the required speed.

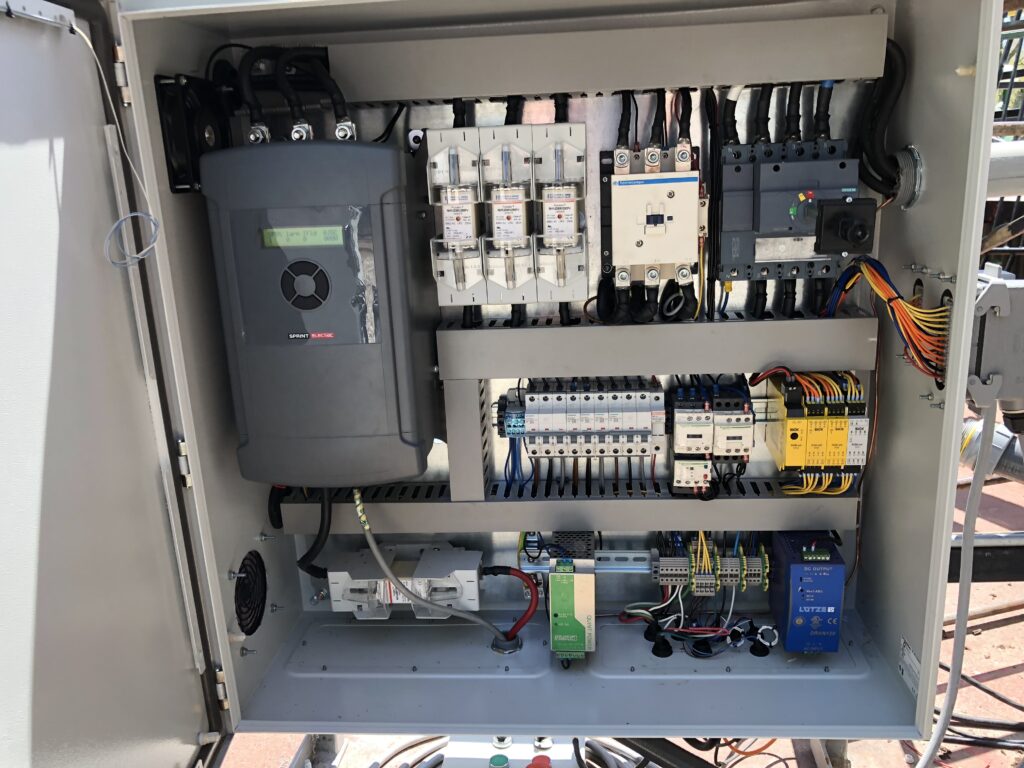

Powered roller coaster cabinet showing retrofitted Sprint Electric DC Drive

If you have a retrofit project you would like to discuss then contact us here or speak to one of our local distributors in our Worldwide network.

*Thank-you to Sean Brian, Director, Amusement Technical for the use of his images and videos