The production of hot strip is a key element of steel production. Roughly half of all steel produced is hot-rolled to strip. Modern mills require precise motor control to provide geometrical precision together with optimum material properties.

Sprint Electric DC Drives operate in hot strip mills all over the world. Our DC Drives can be configured to various levels of sophistication, including embedded Industrial Internet of Things (IIoT) to allow mill-owners to control and diagnose real-time performance outside of the machine-operating zone.

METALS

Applications in the metal industry include smelting, refining and processing of ferrous and nonferrous metals within iron mills, steel mills and aluminium producers, rolled steel and copper foundries.

Metal Processing Applications

A highly demanding industry, it is vital that metal-processing machinery provides consistent performance in an extremely tough environment. Sprint Electric Digital DC Drives provide exceptional performance for machines that need to repeatedly produce high-quality components in difficult operating conditions.

Our DC Drives operate in Europe, Asia Pacific, Middle East, the Americas, China and Russia within a wide variety of metal processing applications such as hot & cold rolling mills, rod & bar mills, skin pass mills, pickle lines, annealing lines, coilers & re-coilers, coating lines, tube mills, tension levelling lines, forging lines, casting lines, foil rolling mills and slitter/separator machines.

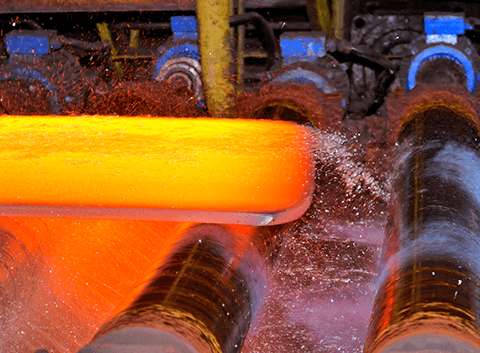

ROLLING MILL

Sprint Electric’s high power 4 quadrant DC Drives provide exceptional motor control up to 980kW in rolling mill applications.

Rolling mills are used to reduce the gauge or change the shape of metal, mills can be hot or cold roll. Hot roll mills heat up the metal to a high temperature so that shaping and forming can be easily accomplished. Cold roll mills adds a further process, a cold reduction mill (normally room temperature). This is followed by further tempered rolling that gives closer dimensional tolerances and increased surface finishes.

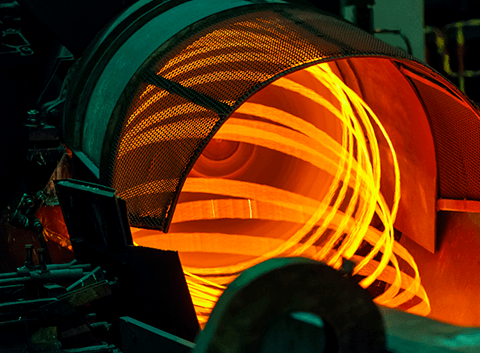

WIRE DRAWING

Our digital DC Drives allows users to easily configure precise machine control for wire drawing applications.

Wire drawing is the process of the reduction of a wire diameter typically from 12mm to 1mm over a process of up to 14 dies. Due to the complex processes involved, speeds vary as the material length increases when it passes through a die. Sprint Electric DC Drives provide accurate torque control regardless of wire speed to provide constant tension throughout the process.

BECOME A DISTRIBUTOR