Extrusion involves forcing molten thermoplastic through a die. Using DC motors up to 600kW, extruders require very precise speed control to ensure consistency of mix and output. Sprint Electric Digital DC Drives feature high bandwidth electronics that provides exceptional speed control. In addition, our Digital Drives can be IIoT (Industrial Internet of Things) enabled to provide real-time diagnostics, control multiple axes or third party drive systems and that can interface with factory automation systems such as SCADA using deterministic Ethernet.

PLASTICS

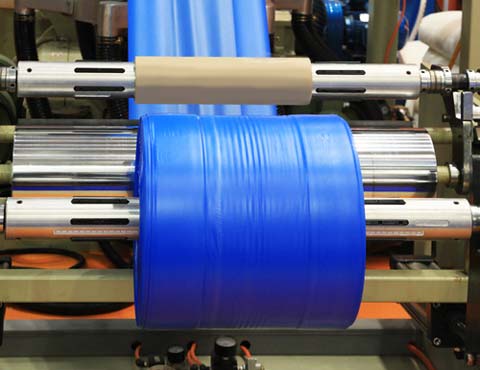

Plastics are produced by forcing dry granulate through a heated extrusion process, often followed by a blown-film machine to produce plastic film, sheets, profiles or pipes.

Plastic Applications

Plastic production is an established commodity production dominated by Chinese, German and USA production. Known for its low-cost requirements, machine designers require stable and consistent performance from Drive systems. Sprint Electric DC Drives are used in many plastics applications with a focus on extrusion machines requiring Drives up to 600kW in output power.

Sprint Electric Digital DC Drives are used for auger feeders, single & twin-screw extruders, vacuum pump drives, reelers, conveying drives, film drives and haul off/caterpillars.

HAUL OFF / CATERPILLAR

Haul off units are there to pull the extruded plastic at a uniform speed with no slippage. This process ensures the uniform dimensions of the plastic extrusion. To achieve precise dimensions, the DC Drive needs to control the motor in constant torque mode with overall supervision of motor speed. Sprint Electric Digital DC Drives provide exceptional torque control over a wide speed range to provide cost effective and reliable solutions for haul-off applications.

SHEET LINE REELER

Plastic extrusion is hauled from the extruder and wound onto reels under strictly controlled conditions. Sheet line reelers are powered by DC motors, which operate under torque-speed control. Torque is varied as the reel diameter changes to ensure constant wrap. Sprint Digital DC Drives provide ready-made function blocks specifically for ‘diameter – speed – torque’ control. In addition, our DC Drives can be programmed to control peripheral drives / axes and act as a PLC to control both the reeler and associated machinery.

BECOME A DISTRIBUTOR